A complicated airbag ship launching project

admin:admin time:2010-12-14

Marine airbag ship launching technology is developing fast nowdays and at the same time it is required to be competent for more complicated launch projects. People who is familiar to this technology may know that to launch a ship with marine airbags it will need the vessel’s supporting blocks not higher than the airbags’ diameters. But if people have to launch a 7280 tons ship with supporting blocks’ heights range from 0.9 m to 2.1 m ,what they should do?

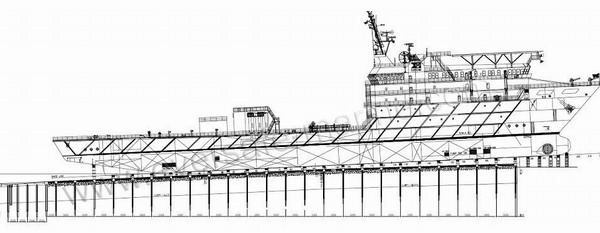

Eversafe Marine engineering company received a invitation from a client to help launch a 7000 tons DSV in Vietnam. That vessel named “CABALLO MARANGO” gets 143 meters total length; 22 meters molded width and 7280 tons launch weight. It is built on a plain ramp which consists of two parts: one is 70 meters long with a 3% angle; another part is 74 meters long with a 4.5% angle. In the ramp only five meters there is a 25 cm wide concrete stripe, the left parts are filled with uncompressed debris. Supporting blocks is arranged to make vessel’s bottom parallel to the 4.5% angle ramp then the height of bottom is getting higher and higher from the knuckle of ramp.

The main difficulty of this launch project is to lift up vessel to remove blocks. There are two practical factors caused the difficlty: the heights of part vessel’s bottom are bigger than the diameters of airbags, most vessel’s gravity is located on the bow which is upon the 3% angle part. Since the vessel’s gravity center fall behind the knuckle of ramp then people have to move vessel forward before the launch.

By several times discussion with shipyard, Eversafe technical teams decided to build temporary platform to enable airbags to lift up vessel. After the lifting up, vessel will be moved forward 30 meters which will make the vessel’s gravity center beyond the knuckle about 10 meters. But a subsequent problem will come up that after vessel moved its stern will get float when in high tide time. Then we have to do more detailed calculation to avoid the possible premature stern float. At last ballast water is employed to antagonize the unexpected stern buoyancy.

On December 7, Eversafe marine engineering company, the subsidiary of Evergreen Maritime, successfully launched a 7280 tons DSV using airbag ship launching technology in Vung Tau Vietnam. It is the second DSV and third vessel launched by Eversafe team for the same client-Strategic Marine (Vietnam).

On December 4th, Eversafe engineers supervised shipyard workers to arrange airbags and pump them to lift vessel with back pull from two 50 tons winches. Limited by the temporary platform, only 30 pieces airbags can be used for lifting. Based on accurate calculation, the lifting work went smoothly but it still took two days to take out all supporting blocks. In 6th morning, low tide time, people began to move the vessel. Because the subsidence of ramp, marine airbags rolled arduously and the friction counteracted vessel’s slip down force which lighten the burden of winches. Total 3 hours it took people to move vessel forward 30 meters and recalibrate marine airbags. After the vessel shift, ballast water was added. On December 8, a ceremony was hold to bless the nice vessel. At pm 3 the launch signal was shot. When steel ropes were chopped down, the vessel started to move swiftly by riding rolling airbags and entered into water smoothly accompanied by scream from crowded watching people. It took 62 seconds from vessel start to total floatation.

This launch project is a rigorous trial of marine airbags and airbag ship launching technology. Some airbags are compressed 80% and their inner pressures reach 0.25 Mpa during the lifting and launch period. Evergreen marine airbags are proved to be reliable for cruel heavy duty. Also for this launch project, airbag ship launch technology exhibited its peerless flexibility and power. To lift the vessel, airbags were arranged to make vessel bottom being parallel to 3% angle ramp; while to launch the vessel, airbags’ pressures were adjusted to make vessel bottom being parallel to 4.5% angle ramp.

People can easily find that to do this launch project airbag ship launching is the best choice. Firstly, airbag ship launching needs no reconstruction of slipway, no heavy lift equipments so it save most money and can send vessel into water in the shortest time. Secondly, airbag ship launching can ensure the safety of vessel. Marine airbags can offer a variational supporting forces to the vessel when they roll on a undulant ramp and those supporting forces are always within the limitation of vessel’s bend resistance.